Project Support

Freight/Transportation/Packaging

AquaBlok® can be packaged and delivered to project sites in a variety of ways, including bags or pails on pallets. Packaging for larger applications typically relies on bulk super sacks usually weighing between 2,400-lbs and 2,700-lbs. Depending on the project site location and transport distance, material can also be delivered in bulk without packaging using covered dump trucks. Transport has been provided by LTL, full truckload, container, intermodal, and by rail. AquaBlok, Ltd. is available to provide logistics support to all of our customers.

Product Installation & Placement

AquaBlok can be placed with most conventional installation equipment. The approach is generally guided by site-specific factors and access to the placement area. The listing above illustrates some of the equipment and installation methods that have been successfully employed.

On-Site Manufacturing

Some projects may require product manufacturing on or near the project site, thus precluding the need for significant packaging and transport. For projects of significant size or material requirements, on-site manufacturing is often more cost-effective. On-site or near-site manufacturing can reduce packaging and freight costs and will save on material handling, storage, and other costs at the project site. Near-site production may also enable the use of just-in-time material delivery for faster installation.

AquaBlok has performed on-site manufacturing in climates and regions ranging from mid-summer in Alabama to mid-winter in Maine. With on-site production having been run in Alaska, Norway, and Australia, AquaBlok is not limited to projects in the Continental US. Contact us for more information about large-scale product installations.

Field Support – Installation QA/QC

AquaBlok can provide on-site representation and assistance in implementation of QA/QC programs. On-site representation by AquaBlok may be required as a warranty condition when AquaBlok is being used on some projects and can be provided for an additional fee. AquaBlok does not place product in the field, but will provide on-site support and work with qualified contractors to ensure appropriate and adequate placement techniques.

Laboratory Support

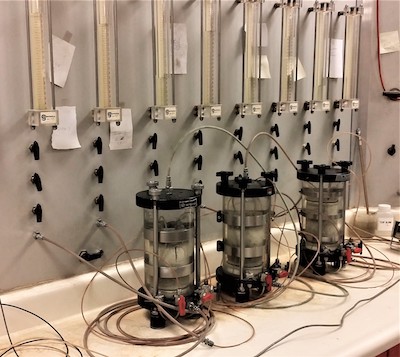

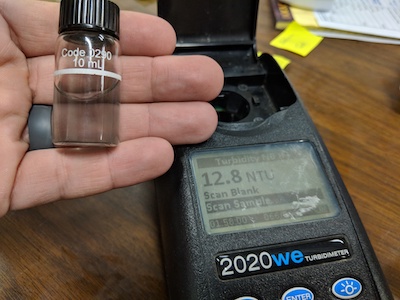

AquaBlok has laboratory facilities and equipment to perform a wide range of basic laboratory testing and to assist in the development and testing of various product formulations.

Project-specific design mixes and coverage rates, within the context of site-specific remedial designs, may require the completion of preliminary laboratory or bench-scale testing. For example, development of cap thickness, slope stability, erosion resistance or other parameters can be evaluated. Typically, this requires site-specific information (e.g. surface/ground water flow velocities) and other relevant data. AquaBlok can assist in the completion of laboratory studies and computer modeling that may be required to address site-specific issues.

While AquaBlok does not typically perform in-house treatability testing on specific reactive or adsorptive materials, the company provides support with designing and monitoring third-party testing. Many different lab tests have been run on AquaBlok materials. These tests, some of which can be seen in the photos to the right, were done in-house or by third-party laboratories.

Project Cost Estimates

Compared to environmental dredging, in-situ capping with AquaBlok and AquaGate®+ can provide a cost-effective solution to managing contaminated sediments in place. Costs for implementing an AquaBlok-based capping remedy will vary widely depending on several project and site-related factors. These will collectively dictate the most appropriate product formulation, cap design and method(s) for cap installation.

The relative scale and location of the project, along with other factors, will dictate whether product is manufactured at AquaBlok’s manufacturing plant or at or near the project site. This distinction has an influence on the total project cost as each approach saves money in different ways.

For example, assuming appropriate support facilities and space are available, on- or near-site manufacturing may not require product packaging and/or significant material transportation. It would, however, include costs associated with mobilization of AquaBlok equipment and personnel to the manufacturing location, local permits, etc. In contrast, product that is manufactured away from the project site would not typically involve any mobilization costs, but would include costs for packaging and transportation (e.g. truckload, rail, etc.).

| Project Planning & Management | Preliminary Laboratory Studies | Preliminary Field Pilot Studies | Cap Design |

| Permitting | Construction Quality Assurance | Construction Quality Control | Confirmation of Amendment Performance |

| Long-Term Performance Monitoring | Cap Maintenance | Sediment Disposal (and Potential Pre-Treatment) | Potential Litigation from Damage to Ecosystem |

AquaBlok provides support to engineers, consultants, and responsible parties to help assess and estimate costs associated with many of the above factors. Please contact us to learn more.